Building Enclosure Commissioning 101 – Part 1

Building Enclosure Commissioning 101, the Why? – Part 1

Building Enclosure Commissioning 101 is relatively new and many teams don’t yet understand its value. I remember attending a seminar on HVAC commissioning at the Pacific Energy Center in San Francisco 18 years ago. This was a new, upcoming service at the time and commissioning agents were working hard to prove their value to building owners. A developer in the audience asked “Why do we need HVAC Cx agents? What are mechanical engineers for? Just how many people will it take to get the building right?” I was reminded of this episode when one of the owner representatives present at a building enclosure commissioning (BECx) talk I gave asked me: What are the architects not doing that we need Enclosure Cx Agents? In this 2-part blog I am going to explain the “why” behind BECx (Building Enclosure Commissioning 101).

Just as HVAC Cx was in its infancy 2 decades ago, so BECx is starting to become known today. No developer or building owner questions the need for HVAC Cx today; they know its value and the problems that can arise if the HVAC system is not commissioned. And it’s not just the HVAC system, present day building management systems, lighting systems etc. are all complex enough to merit a specialist testing to verifying all systems are working together and functioning as designed.

As an architect with almost 2 decades of experience designing and managing building projects, I am intimately familiar with the process of developing drawings and specifications for construction. This makes me well suited to perform building enclosure commissioning.

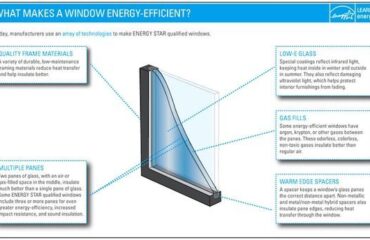

Construction details are pulled from in-house detail libraries and modified to suit each project. Alternatively, they are downloaded from product manufacturer websites and again edited to fit the project. Editing of these details is done by teams of drafters who are learning the craft and don’t necessarily understand the meaning behind the various lines they see on their computer screens. While these details are checked (or supposed to be checked) by an experienced architect, we are relying on that one person to determine the integrity of a building when it comes to its performance vis-à-vis rain, air leakage (which is the main contributor of mold) and heat transmission (which affects energy performance and occupant comfort) across the building skin.

Envelope Commissioning Verse Waterproofing

It is because we understand the importance of waterproofing a building, and the fact that we cannot rely only on architectural drawings to ensure water tightness, that we have waterproofing consultants on projects. We hire waterproofing consultants to look at each exterior detail and add multiple layers of waterproofing (i.e. add redundancy). In addition to these architectural details, there are several electrical and plumbing penetrations that are made in the building skin and the choice of sealant to plug the penetrations is left to each subcontractor doing the installation.

Enclosure Commissioning During Construction

Construction personnel excel at means and methods, not product choice and specification – product selection is the domain of designers. Sealants (along with some other products) form the first and often times the only line of defense against air leakage and water intrusion and should be selected with great care after considering many different factors. When this selection is left to be made downstream by the installer, not only performance, but system warranties get compromised as well. By “system warranties” I mean warranties for the weather resistive barrier, air barrier, thermal barrier, etc – each and every barrier (a.k.a control layer) that is a part of the building exterior skin. Each of these barriers are really “systems”, with their own accompanying palette of sealants, tapes, patching compounds etc. that have to be meticulously installed according to manufacturer instructions, in order to preserve the product warranty. In most cases, the tapes, sealants, and other compounds used within exterior assemblies, belong to many different manufacturers. So when problems are discovered with the building, this process of incomplete drawing + specifications, mish-mash of products, compromised warranties and non-inspected installations, leads to lots of finger pointing.

Stay tuned for the 2nd part of this blog that addresses more about areas of concern with current industry practices and the building enclosure commissioning 101 approach to enclosure systems.

PS. Here’s the link to Part 2.