IAQ Issues in a LEED Building – Part One

Air Quality Problems in the EPA’s San Francisco LEED EBOM Building

IAQ Issues in a LEED Building Part ONE

At the end of February 2016, NBC ran a segment investigating whether the EPA Region 9 building, at 75 Hawthorne Street in downtown San Francisco, was a Sick Building. All answers pointed to yes. In the past two years 64% of the 139 employees surveyed thought the building was making them sick, complaining of headaches, dizziness, nausea, fatigue and throat irritation and other IAQ issues. Workers blame the EPA while the EPA blames the management company, Hines, for not providing proper ventilation. Regardless of who shoulders the responsibility, the Environmental Protection Agency’s IAQ issues in a LEED EBOM Platinum building causing illness, is worth examining. What went wrong and how can we learn from it?

In order to meet LEED’s indoor air quality credit, a building can choose to perform a flush out or be tested for VOCs. The EPA building chose the flush out. A flush out can be done in two ways: before occupancy or post occupancy. If you are doing the former the general contractor must install new filtration media and flush out the building by pumping 14,000 cubic feet of outdoor air in for every square foot of floor area. This should be done while maintaining a temperature of at least 60 degrees F with a relative humidity no higher than 60%. The post occupancy option, called a phase out flush, pumps 3500 cubic feet of outdoor air in for every square ft. of floor area, while maintaining a ventilation rate of 0.30 CFM. This is done until 14,000 cubic feet of outdoor air is pumped into the space.

IAQ Issues and Air Circulation

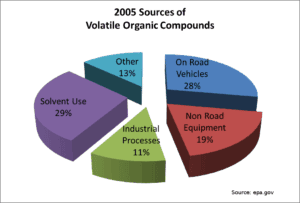

Both methods require that a tremendous amount of air circulate the building while expelling potentially contaminated indoor air. Manufacturers say that the majority of VOCs are emitted after a 7-10 day cure time, so one would think that the majority of VOCs would have been removed from the EPA building before or soon after occupancy. This was not the case; recent testing revealed elevated levels of toluene, xylene, and ethylbenzene, carcinogenic VOCs. It is no surprise that people have been reporting illness since the building was renovated in 2014.

Do you know what kind of flush out the building did?

Was the flush out performed incorrectly? Is there something in the building that is still off gassing? Perhaps it is both. LEED’s EBOM Materials and Resources credit MRc3 “Sustainable Purchasing- Facility Alterations and Additions”, (which 75 Hawthorne met) mandates the use of low emitting VOC products for base building materials permanently or semi-permanently installed. Some of these include, paints, sealants, and coatings. The credit however does not cover furniture. The furniture credit, which 75 Hawthorne also met, addresses how the materials are sourced, however it does not require furniture to meet any chemical standards. As a result, it is possible for furniture to have a fair amount of VOCs without anyone knowing. Nevertheless, wouldn’t the increased ventilation required to achieve LEED EBOM Platinum have helped to expel the majority of these VOCs?

The EPA argues that people are getting sick because Hines is not ventilating the building properly. This may be the case, the answer is still pending. What is important to take away from this incident is that even the highest level of LEED certification cannot promise a healthy building if the materials inside it are filled with chemicals that are not properly expelled or diluted due to poor ventilation. It is ultimately up to the building owner and management to maintain LEED guidelines as well as implement their own health and safety measures.