Industrial Facility – Indoor Air Quality (IAQ) Study

Industrial Facility – Indoor Air Quality Study

San Francisco Bay Area, CA

Industrial Coin Counting Facility Summary:

Client was interested in measuring effects to IAQ, specifically increased airborne particulates caused by new coin counting machinery in an industrial facility.

Coin Counting IAQ Investigation Process:

HBS conducted a comprehensive interior air quality investigation to determine possible contaminants and pathways. An inspection of the industrial machinery and mechanical systems, including plumbing and HVAC, was performed. After inspection a 7-day particle count survey was proposed, accepted and performed in the main coin counting area. Observations and data were analyzed to develop hypotheses regarding particulate contaminants and possible sources, and to address potential air quality improvements.

Coin Counting IAQ Investigation Highlights:

A 7-day laser particle counter survey was performed to measure fine and coarse respirable airborne particles affecting indoor air quality. The particle counter was placed in the center of the work area, in the breathing zone for a majority of workers. Particles were measured on 6 channels, measuring particle sizes in the 0.3 micron, 0.5 micron, 1.0 micron, 2.5 micron, 5.0 micron and 10.0 micron ranges. A 3-minute air sample was taken every 15 minutes for 7 days and data was logged and graphed.

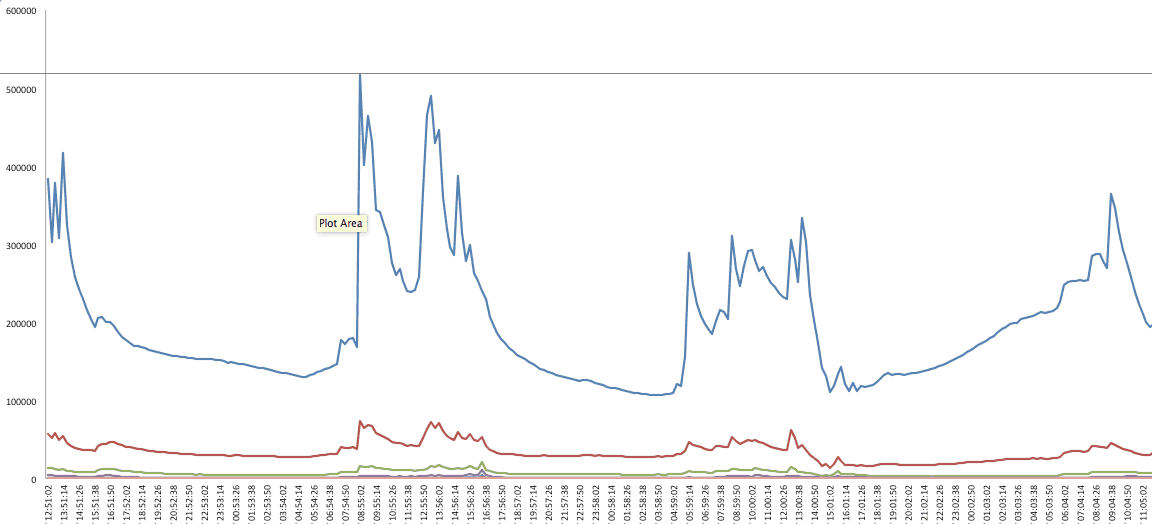

The chart below plots particle mass vs. time for a 1 week period, with Particle Mass on the vertical axis and time on the horizontal axis. The different colored lines represent different particle sizes:

The graph shows strong correlation with operation of coin counting machines and increased particulates in the air samples. The mechanical agitation caused by the action of the process apparently allowed significant particulates to enter the air in the facility. The survey revealed significant spikes in particulate counts when the machines were started, with significant reductions when the facility was not in operation i.e., at night. The current HVAC systems did appear to reduce airborne particulate levels over time via filtration. However, the HVAC filtration system was insufficient to reduce particle counts to levels measured when the machines were idle.

Fine and coarse particulates are regulated by the EPA and OSHA, and have been shown to be detrimental to respiratory health. Current coin counting machinery appeared to be the source of increased interior particulates and the investigation revealed a need of corrective action for indoor air quality. Workers had been wearing particulate filtration masks for PPE (personal protective equipment) as required by OSHA, but the client wished to explore options improving for overall IAQ. HBS worked with the client and HVAC engineers designing a system to segregate machinery from workers, as well as direct machinery airflow away from workers, directly into an improved particulate filtration system. The system not only improved IAQ by reducing particulates in work areas, but also reduced outside air pollution by filtering air that was exhausted to the exterior. The system complied with BAAQMD (Bay Area Air Quality Management District), CARB (California Air Resources Board) and EPA regulations.

Follow up testing and monitoring verified effectiveness of the upgrades and that the facility would maintain healthy interior air quality.

Industrial Facility Conclusion:

Our investigation revealed deficiencies in IAQ and possible sources. HBS recommended further testing to verify sources and quantify specific contaminants. Our team worked with the client to propose permanent solutions. HBS also provided independent third-party testing and verification that the implemented solutions were effective, and that IAQ was measurably improved. Periodic monitoring will assure systems continue to operate as designed, and assure healthy IAQ into the future.

The end result is a cleaner operation with significantly improved IAQ.

HBS Team:

David Sasse, Senior Environmental Inspector, CMI, CIE

Council Certified Microbial Investigator

Council Certified Indoor Environmentalist

Board awarded by the American Council for Accredited Certification